Putting medical tests to the test

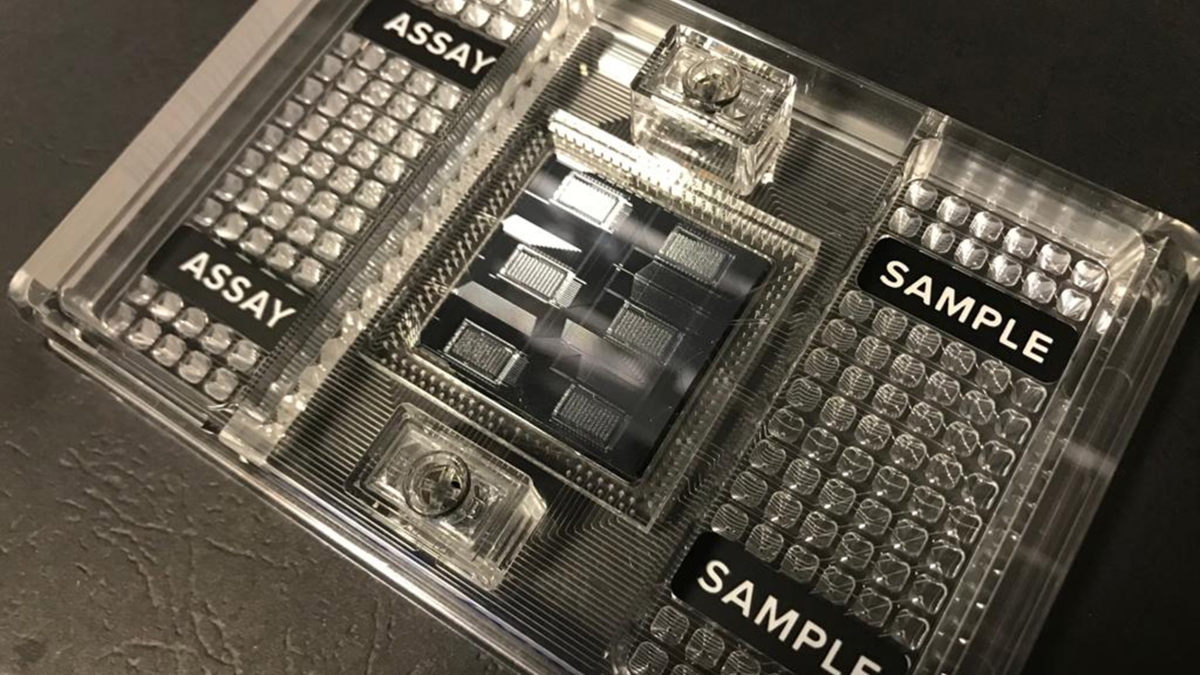

Arizona State University Fulton Professor of Microelectronics Krishnendu Chakrabarty collaborated with colleagues to develop methods that detect whether a lab-on-a-chip medical test is fraudulent or has been tampered with. Photo courtesy Navajit Singh Baban

Biofluidic chips are widely utilized in medical testing for polymerase chain reaction, or PCR, tests, which use lab-on-a-chip devices to diagnose various diseases or genetic changes. Although originally invented in the 1980s and widely used in the scientific community, PCR tests gained prominence among the wider public during the COVID-19 pandemic. They are held as the gold standard for accuracy among diagnostic tools.

However, PCR tests and other lab-on-a-chip devices are accurate only if the chips are built correctly, undamaged, properly used and have not been tampered with. Lab-on-a-chip tests must be processed and handled by multiple parties before reaching their destinations in medical facilities. This process presents the risk of chips being damaged or tampered with by malicious entities in the supply chain for financial gain.

The effects of inaccurate results from lab-on-a-chip tests can have grave consequences. For example, a false negative result can cause accidental spread of viral diseases or failure to alert scientists of a medication’s side effects before its use on humans.

To ensure accuracy and reliability of lab-on-a-chip tests, Krishnendu Chakrabarty, Fulton Professor of Microelectronics in the Ira A. Fulton Schools of Engineering at Arizona State University, and Ramesh Karri, a professor of electrical and computer engineering at New York University’s Tandon School of Engineering, collaborated with researchers led by New York University Abu Dhabi postdoctoral associate Navajit Singh Baban on a National Science Foundation-funded project to develop two types of watermarks that activate when a legitimate and properly functioning test is used. One watermark uses a dye only visible under ultraviolet light, and the other causes a reaction when force is applied.

The science journal Lab on a Chip published the team’s research in an associated paper, “Material-level countermeasures for securing microfluidic biochips,” in August.

“Trust is very important in biomedical engineering and clinical diagnostics,” says Chakrabarty, a faculty member in the School of Electrical, Computer and Energy Engineering, part of the Fulton Schools. “We are trying to lower the cost of diagnostics and health care to make it available in remote locations with point-of-care testing, and that can only be done if the user trusts the devices.”

Ensuring accurate health care

To the naked eye, watermarked chips look no different before their use; all is revealed only for those who know where to look.

Lab-on-a-chip devices using dye as a watermark incorporate the feature into the chip’s existing architecture. Many lab-on-a-chip tests have tiny valves known as microvalves, which direct fluid through the chips when activated with samples.

“You can think of these valves like a very, very thin membrane balloon,” says Baban, who specializes in research in mechanobiology and microfluidic biochip security. “When pressure is applied, it will deform, and these dyes will respond in a mechanical way and show signatures.”

The dye is added to the chip’s microvalve system and does not interfere with the test results. When the test is run, the dye reveals a signature spot that lab technicians check with an ultraviolet light to ensure the test is legitimate and accurate.

While Chakrabarty’s expertise is in microelectronics, he says the movement of fluids in microvalves work similarly to electronic chips channeling electrical current through transistors. The use of dye is similar to doping microelectronic chips, a process in which substances are added to chips to control the flow of electrical current, which changes characteristics such as impeding or enhancing electricity conduction.

The second type of watermark shows if a test is legitimate by analyzing the chemical composition of the chip through physical force.

“Initially, these materials are liquid and through the use of heat they’re made solid,” Baban says. “During this transition, one can add all these bad chemicals and alter the composition of the material, potentially hampering the working of the chips.”

Force is applied by a small metal punch tool connected to software that can detect how much resistance the chip material provides to the tool when pressure is applied. An artificial intelligence model trained on data from legitimate tests determines if the material provides the required amount of resistance for the test to be deemed authentic.

Increasing need for an expanding industry

According to medical journal The Lancet, 47% of the world does not have access to diagnostic tests. Inexpensive point-of-care tools are essential to help meet this need. Lab-on-a-chip devices, being simple and cheap to build, are in high demand to increase access to accurate medical tests. Market research company MarketsandMarkets estimates the revenue for microfluidics devices will grow from $22.3 billion to $41.1 billion between 2023 and 2028, an increase of more than 80%.

Simultaneously, the U.S. Senate has recognized a need for medical device security and included measures to address the topic in the spending bill to fund the government through September. With dramatic increases in both the need for lab-on-a-chip tests and medical device regulation, Chakrabarty emphasizes the importance of the research team’s work for the future of the medical device security and testing fields.

“This is a cost-sensitive market,” he says. “These are disposable one-time use devices, so they can’t cost much. One way to lower the cost is to have a distributed supply chain because there are specific entities that do the best job on specific parts of production. We are providing the mechanisms so you can validate various steps in this entire assembly process.”

Josh Hihath, a professor of electrical engineering in the Fulton Schools and director of the Biodesign Center for Bioelectronics and Biosensors in ASU’s Biodesign Institute, praises the research for reducing the risks associated with lab-on-a-chip devices.

“Developing pipelines that allow us to verify the providence of sensing and health devices is extremely important, as the risks of device failure are so profound,” Hihath says. “This approach provides an intriguing method to extend trustable pipelines into the microfluidics space.”

More Science and technology

ASU-led space telescope is ready to fly

The Star Planet Activity Research CubeSat, or SPARCS, a small space telescope that will monitor the flares and sunspot activity…

ASU at the heart of the state's revitalized microelectronics industry

A stronger local economy, more reliable technology, and a future where our computers and devices do the impossible: that’s the…

Breakthrough copper alloy achieves unprecedented high-temperature performance

A team of researchers from Arizona State University, the U.S. Army Research Laboratory, Lehigh University and Louisiana State…