Testing pavements to prepare for changing traffic patterns

Hasan Ozer (left), an associate professor of civil, environmental and sustainable engineering in the Ira A. Fulton Schools of Engineering at Arizona State University, and Ashraf Alrajhi, a civil, environmental and sustainable engineering graduate student, prepare a pavement sample for the dynamic triaxial testing system. The system, developed by Ozer and a team of ASU researchers, is helping illuminate asphalt deformation challenges such as rutting, which can be dangerous to drivers and costly to repair. The system is already contributing to addressing potential rutting issues related to changing traffic patterns from the introduction of automated and connected semitrucks on highways and increased airport traffic on taxiways and runways. Photo by Erika Gronek/ASU

Do you ever feel stuck in a rut — a literal rut in the road? These permanent deformations in asphalt pavement happen everywhere, but they can be particularly challenging in Arizona due to the state’s high temperatures, slow traffic speeds due to congestion and other factors.

Hasan Ozer, an associate professor of civil, environmental and sustainable engineering in the School of Sustainable Engineering and the Built Environment, part of the Ira A. Fulton Schools of Engineering at Arizona State University, is an expert in assessing the structural performance of pavements to advance sustainable transportation infrastructure.

“Asphalt pavement deformation is one of the most critical distresses closely monitored by government agencies, especially for highways,” Ozer says. “Maintaining rutting below the critical threshold is crucially important for the safety of the traveling public.”

When ruts get deeper than a quarter of an inch, the risk of hydroplaning increases in wet conditions and can be dangerous to cyclists in these lanes.

Ozer says increased rutting is also a warning of poor pavement health. Many roads use different layers of pavement materials on the surface and foundation. If one of these materials is ill-suited to environmental and use conditions, it contributes to rutting when certain traffic loads and patterns are present.

“If rutting cannot be prevented, the repairs can be very costly and can lead to complete reconstruction or very deep repairs,” Ozer says.

Ozer is a researcher in ASU’s Pavement Analysis and Design group, which engages with national professional organizations, government agencies and private entities to enhance pavement materials and technology. He also founded the Southwest Pavement Technology Consortium with a vision of creating a pavement alliance and hub that tightly connects academia, industry, and state and local agencies in Arizona.

Ozer and his research team at ASU have developed an innovative, first-of-its-kind testing method that mimics moving traffic load patterns that cause rutting and other asphalt pavement deformation problems. Designed and manufactured in Tempe, Arizona, the dynamic triaxial testing system can imitate a versatile range of independently applied horizontal and vertical pressure patterns.

Surface samples of asphalt pavement can be tested at temperatures up to nearly 160 degrees Fahrenheit to replicate hot summer conditions. This is especially useful as Phoenix grows hotter. The city recently broke a heat record related to sustained high temperatures.

“The first version of our dynamic triaxial system helped us better understand some of the key, fundamental concepts underlying permanent deformation in asphalt pavements,” Ozer says, noting the team plans to develop new and upgraded versions of the testing unit to be able to handle larger sample sizes to address the kinds of stresses induced by very large aircraft such as Boeing 777 airliners.

The testing system has already contributed to understanding challenging engineering problems for critical infrastructure, including highways and airports, which are increasingly affected by rutting due to heavy truck and aircraft loads under extreme temperatures.

Ozer says results from the research using the dynamic triaxial testing system can lead to better materials and standards that help prevent safety hazards as well as costly and disruptive infrastructure repairs in Arizona, across the country and even around the world.

Protecting highway pavement from heavy traffic

Lines of slow trucks are a common sight for Arizonans traveling on interstate highways. In the near future, these trucks may use automation to travel in a more organized and efficient formation.

Original equipment manufacturers like MAN Truck & Bus, Scania and Volvo are developing and testing trucks in the U.S., Canada and the European Union that use automation and connected communications to move cargo more efficiently using a principle known as platooning.

Like a freight train with many cars traveling along a track, platoons of two or more automated and connected trucks travel closely together, single file along a highway. Preliminary findings in North America and Europe suggest this would cut carbon emissions, improve safety and reduce traffic congestion.

However, this new traffic pattern could lead to increased rutting or other unknown pavement deformation issues the materials were not designed to handle. To investigate potential problems, Ozer has been using the dynamic triaxial testing system to learn more about how platooning strategies affect pavement performance in a research project being conducted in collaboration with the U.S. Department of Transportation’s Center for Connected and Automated Transportation, or CCAT, at the University of Michigan and with partners at the University of Illinois Urbana-Champaign’s Illinois Center for Transportation.

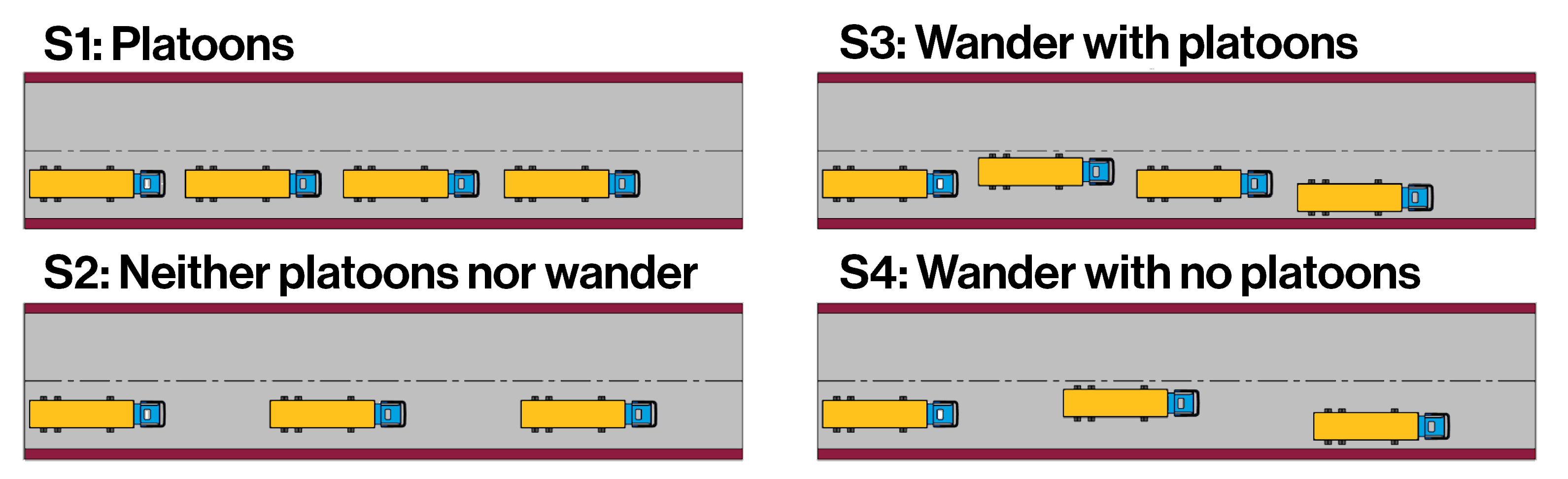

Four scenarios for automated and connected truck formations include closely spaced platoons in exact formation or with variation called “wander,” and spread-out formations in alignment or with wander. Ozer is part of a multi-institution research team in which he and his ASU research team are using the dynamic triaxial testing system to determine the effect of automated and connected trucks on asphalt pavement. Graphic courtesy Hasan Ozer

Automated and connected trucks can either travel in platoons that follow exactly the same path or in a pattern called “wander,” in which the trucks are not perfectly aligned. They can also stick closely together in a platoon formation or spread out as a nonplatooned set. Ozer’s team studied four platooning scenarios and how they impact the progression of rutting at different temperatures.

The researchers thought formations where trucks were more spread out, and therefore allowed the pavement to “rest” between truck loads, would reduce deformations and prevent additional distress.

“But we have shown the contrary with our triaxial repeated load permanent deformation experiments,” Ozer says. “We demonstrated that a reduction in rest period, or shorter distance between trucks, can help reduce permanent deformations" as long as they travel in wandering patterns rather than following the same tire paths in channelized traffic.

This research, in partnership with CCAT, demonstrates the importance of infrastructure considerations in the implementation of automation and driver-assistance technology. Ozer continues to examine research questions regarding the readiness of infrastructure, the effects of new traffic patterns and how the roadways can enable the benefits of these technologies.

Ensuring smooth taxiing and operations at airports

Phoenix Sky Harbor International Airport’s runways withstood more than 418,000 takeoffs and landings in 2022. With air travel traffic setting records at the airport so far in 2023, that’s a lot of stress on the runways, taxiways and apron pavements.

Additionally, nearly half of Americans plan to travel more this year, and peak-summer international air travel is forecast to be much busier than last year.

Busy airports often have rapid-exit taxiways to help aircraft leave the runway more quickly and allow planes to land or take off more often. These areas between the runways and gates are critical for airport operations and are the biggest source of airport pavement distress as aircraft turn at high speeds.

In a research project funded by a collaborative program between the U.S. Federal Aviation Administration and the National Asphalt Pavement Association led by Rutgers University with collaborators at the National Center for Asphalt Technology, Ozer is using the dynamic triaxial testing system to conduct advanced experiments that will help illuminate the root causes and various forms of pavement failures at airports.

“We demonstrated in the proposal stage that our triaxial system can simulate the shear type of loading induced by aircraft tires under very high pressure and loads while they are turning onto the high-speed exits from runways,” Ozer says. “This is a unique capability in a triaxial system that requires independent and dynamic control of vertical and horizontal axes of loading.”

Other triaxial testing systems can only apply fixed horizontal pressure, while the system Ozer’s team developed at ASU can apply a wider range of dynamic pulses in horizontal and vertical directions. This is helpful when testing the impact of shear types of stresses in which heavy loads slide horizontally across the pavement surface.

“With such control on both the vertical and horizontal loading axes, we were able to simulate 3D stress states induced by aircraft tires while they are maneuvering on the pavement surface,” Ozer says, noting that ASU's equipment is a unique testing system that can do this for asphalt pavements versus other pavement types.

The ASU team is working closely with pavement engineers and researchers at the Federal Aviation Administration’s William J. Hughes Technical Center in Atlantic City, New Jersey, to advance pavement technologies and develop methods and specifications for smooth and cost-effective airport operations. Ozer says he and his team partner with the Airport Technology Research and Development branch at the William J. Hughes Technical Center for various research and training activities involving airport pavements.

The team will test pavement mixes from airports in Tucson, Arizona, Dothan, Alabama, and Tampa, Florida, to represent different climatic zones and regional materials.

The results will help develop construction and material specifications that can be used by the Federal Aviation Administration to ensure airports are using pavements that can withstand the stresses of increased aircraft traffic.

More Science and technology

Uncovering a pandemic’s ‘perfect storm’

In 2020, the COVID-19 pandemic shut down the world and claimed more than 3 million lives, creating reverberations that we still…

Inaugural ASU–Science Prize winners use AI to help farmers, trafficking victims

From continent-spanning satellite imagery to distributed criminal networks hiding online, some of our most intractable challenges…

From leadership to influencers: Why people choose to follow others

For a long time, most scientists believed that early human hunter-gatherer societies were mostly equal, with little hierarchy or…