ASU researcher clarifies rapid glass-formation process with wide-ranging applications

Solar cells produced by vapor deposition of glass. Photo courtesy ASU's School of Molecular Sciences

Glass is formed by vapor deposition through a process in which vaporized material is condensed onto a substrate, layer by layer, to create a solid glass film. This method involves heating the source material until it vaporizes, then allowing the vapor to deposit on a cooler surface in a controlled environment, often under a vacuum.

The result is glass with a precise thickness and uniform properties, often used in advanced technological applications. These applications include thin-film coatings for optical lenses, such as anti-reflective coatings for eyeglasses and camera lenses, protective and functional layers in semiconductor devices, including integrated circuits and solar cells, and in OLED (organic light-emitting diode) displays, such as those used in smartphones and flat-screen televisions.

The factors that determine the quality of the glass produced, however, were not clearly understood. Determining these factors can allow manufacturers to fine-tune the processes needed, thereby making glass production more efficient and with higher quality.

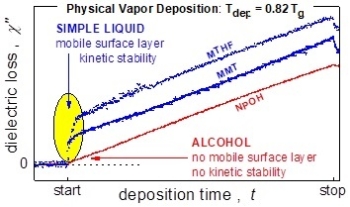

Ranko Richert, a professor in Arizona State University's School of Molecular Sciences, recently published a paper that details how glass quality is affected by production processes. Richert was able to determine the correlation between glass quality and the presence of a mobile surface layer during glass formation by vapor deposition. The result is an improved quality of glass resulting from a mobile surface layer as the glass is formed.

“This technique produces glasses of a high stability that would require at least 1,000 years of aging if produced otherwise,” Richert said.

His paper, “Dielectric Study of n-propanol during Physical Vapor Deposition: No Surface Mobility and No Kinetic Stability,” was published in The Journal of Physical Chemistry B. This research is a collaboration with Mark Ediger of the University of Wisconsin–Madison and supported by NSF chemistry division under CHE-2153944.

“This study observed a clear correlation between the existence or lack of a mobile surface layer during deposition and the resulting high or low stability of the glass,” Richert said. “The improved understanding of the origin of the unique properties of vapor-deposited glasses may lead to better materials.”

More Science and technology

ASU professor honored with prestigious award for being a cybersecurity trailblazer

At first, he thought it was a drill.On Sept. 11, 2001, Gail-Joon Ahn sat in a conference room in Fort Meade, Maryland. The cybersecurity researcher was part of a group that had been invited…

Training stellar students to secure semiconductors

In the wetlands of King’s Bay, Georgia, the sail of a nuclear-powered Trident II Submarine laden with sophisticated computer equipment juts out of the marshy waters. In a medical center, a cardiac…

ASU startup Crystal Sonic wins Natcast pitch competition

Crystal Sonic, an Arizona State University startup, won first place and $25,000 at the 2024 Natcast Startup Pitch Competition at the National Semiconductor Technology Center Symposium, or NSTC…