ASU researcher clarifies rapid glass-formation process with wide-ranging applications

Solar cells produced by vapor deposition of glass. Photo courtesy ASU's School of Molecular Sciences

Glass is formed by vapor deposition through a process in which vaporized material is condensed onto a substrate, layer by layer, to create a solid glass film. This method involves heating the source material until it vaporizes, then allowing the vapor to deposit on a cooler surface in a controlled environment, often under a vacuum.

The result is glass with a precise thickness and uniform properties, often used in advanced technological applications. These applications include thin-film coatings for optical lenses, such as anti-reflective coatings for eyeglasses and camera lenses, protective and functional layers in semiconductor devices, including integrated circuits and solar cells, and in OLED (organic light-emitting diode) displays, such as those used in smartphones and flat-screen televisions.

The factors that determine the quality of the glass produced, however, were not clearly understood. Determining these factors can allow manufacturers to fine-tune the processes needed, thereby making glass production more efficient and with higher quality.

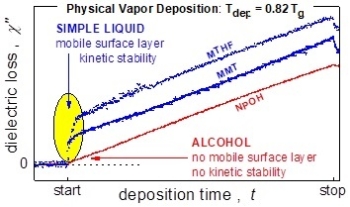

Ranko Richert, a professor in Arizona State University's School of Molecular Sciences, recently published a paper that details how glass quality is affected by production processes. Richert was able to determine the correlation between glass quality and the presence of a mobile surface layer during glass formation by vapor deposition. The result is an improved quality of glass resulting from a mobile surface layer as the glass is formed.

“This technique produces glasses of a high stability that would require at least 1,000 years of aging if produced otherwise,” Richert said.

His paper, “Dielectric Study of n-propanol during Physical Vapor Deposition: No Surface Mobility and No Kinetic Stability,” was published in The Journal of Physical Chemistry B. This research is a collaboration with Mark Ediger of the University of Wisconsin–Madison and supported by NSF chemistry division under CHE-2153944.

“This study observed a clear correlation between the existence or lack of a mobile surface layer during deposition and the resulting high or low stability of the glass,” Richert said. “The improved understanding of the origin of the unique properties of vapor-deposited glasses may lead to better materials.”

More Science and technology

Largest genetic chimpanzee study unveils how they’ve adapted to multiple habitats and disease

Chimpanzees are humans' closest living relatives, sharing about 98% of our DNA. Because of this, scientists can learn more about human evolution by studying how chimpanzees adapt to different…

Beyond the 'Dragon Arc': Unveiling a treasure trove of hidden stars

NASA's James Webb Space Telescope (JWST) has set a new milestone: capturing images of over 40 individual stars in a galaxy so distant that its light has traveled since the universe was only half its…

ASU selected as home and partner for CHIPS and Science Act-funded national facility for semiconductor advanced packaging

Following a week where a spirited effort by the Sun Devil football team captured the nation’s attention in the Peach Bowl, it is Arizona State University’s capability as a top-tier research…