While the CHIPS and Science Act was signed into law less than six months ago, releasing $52 billion over five years for a push to improve national security technology, Arizona State University has been working to prepare for this opportunity.

Grace O’Sullivan, vice president of corporate engagement and strategic partnerships for ASU’s Knowledge Enterprise, said that the university began thinking about its role in researching and developing semiconductor manufacturing five years ago, working with many partners along the way.

“It’s an interdisciplinary effort to make all of this work between government agencies, universities and community colleges, and these things don’t happen overnight,” she said during a webinar on Friday about the CHIPS Act, sponsored by the Morrison Institute for Public Policy at ASU. She was joined on the webinar by Sean Fogarty, vice president of international business development for the Greater Phoenix Economic Council.

“GPEC and ASU, under the vision of ASU President Michael Crow, have been planning this for years.”

RELATED: More microelectronics news out of ASU

Arizona is going to be a major player in this initiative, thanks to a monumental investment by the Taiwan Semiconductor Manufacturing Company (TSMC), which is building two gigantic chip-fabricating centers in north Phoenix.

“TSMC said they chose Arizona because of the cooperation between public and private entities, and we were proud of that and continue to work as a team,” O’Sullivan said. She was part of a state team that visited Taiwan three years ago during the pitch to attract the company here.

Part of Arizona’s preparation to build up America’s semiconductor capacity is the New Economy Initiative, a massive collaboration among the state’s three public universities, private companies and state government to bring Arizona to the frontier of high-tech industry.

Funded by the state, the New Economy Initiative’s goals are to create 40,000 new high-wage jobs by 2041, increase economic output to $6.9 billion by 2032 and double the return on the state’s investment by the same year.

ASU will be a major player in several ways, including workforce development, increasing the number of engineers and in bridging the critical “lab to fab” gap — the time lag between when technology is invented and when it’s ready to be fabricated and put into use.

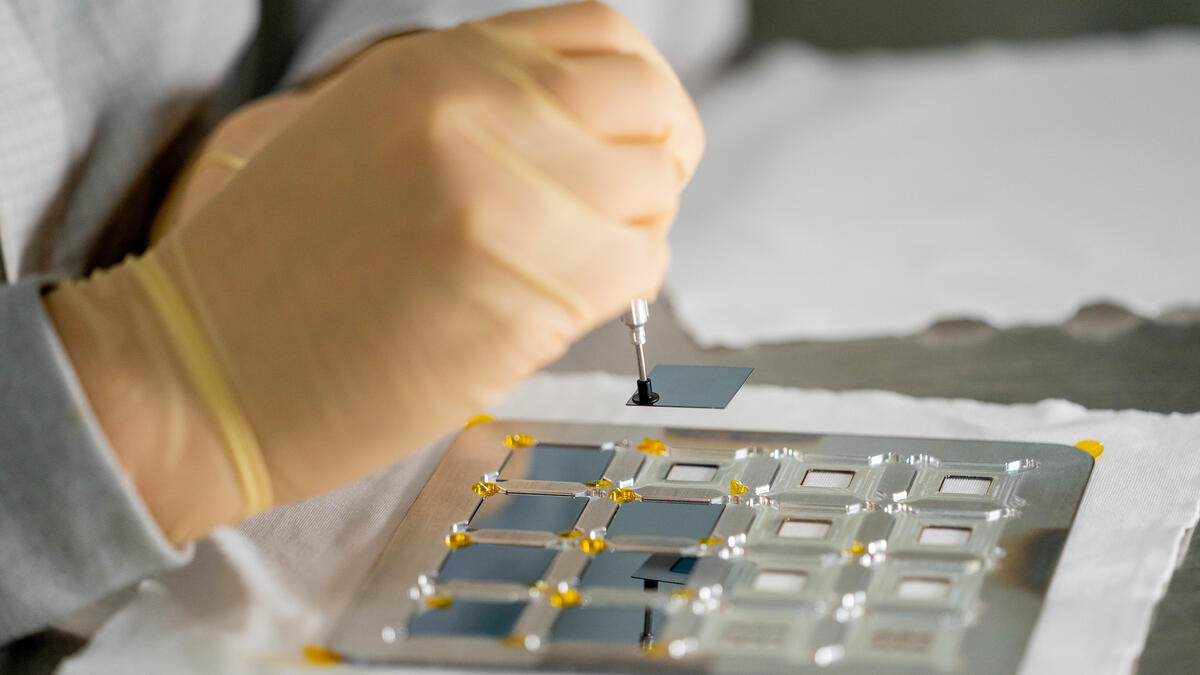

One important component to that will be ASU’s MacroTechnology Works in Tempe, a unique lab and fabrication space that is open to both university researchers and community partners, from tiny ventures to big corporations.

“We’ve had a strong history in Arizona when Motorola opened its fabrication here in the 1950s. ASU acquired that fab and renovated it into the MacroTechnology Works in ASU’s research park,” O’Sullivan said, adding that the U.S. imports more than 90% of the microchips it uses.

“U.S. manufacturing capacity has eroded from 37% of the market to 12% today,” she said.

“A lot of it was because it was cheaper to make things overseas, and also the U.S. didn’t invest as heavily in these industries with incentives as much as countries in Asia did.

“We’re now trying to capture the moment on how Arizona is becoming ‘Semiconductor Central.’”

Fogarty said that Taiwan Semiconductor’s $40 billion investment is one of the largest foreign direct investments in U.S. history and will create a massive ripple effect in everything from shopping to K–12 education.

“It will create 4,500 high-wage jobs, lead to over 21,000 construction jobs and over 13,000 jobs at supplier companies,” he said.

Since July, the Greater Phoenix Economic Council has helped 22 companies relocate here, bringing 4,800 jobs.

Fogarty said the plants will have a lot of jobs that don’t require a bachelor’s degrees.

“For every engineer TSMC has on staff, they probably need four to six technicians,” he said, noting that the community colleges have started to offer “boot camps” for those jobs.

The goal is economic mobility, he said.

“It’s not just PhDs and masters and bachelors we need. It’s also high school-leavers we’re hoping to help, and people in other industries who can be reskilled to take on these high-wage jobs,” he said.

ASU has leveraged its expertise at several points along this multiyear initiative, O’Sullivan said, from having faculty involved in drafting parts of the legislation to having the Kyl Center for Water Policy advise local leaders on water use by semiconductor manufacturers.

“We were just visiting with TSMC this morning to talk about talent needs,” she said.

“We want to be that epicenter of innovation and design, bringing all of our assets.”

Top image: A researcher works at the ASU MacroTechnology Works lab and fabrication space in Tempe. Photo by Samantha Chow/ASU News

More Science and technology

Breakthrough copper alloy achieves unprecedented high-temperature performance

A team of researchers from Arizona State University, the U.S. Army Research Laboratory, Lehigh University and Louisiana State University has developed a groundbreaking high-temperature copper alloy…

4 ASU researchers named senior members of the National Academy of Inventors

The National Academy of Inventors recently named four Arizona State University researchers as senior members to the prestigious organization.Professor Qiang Chen and associate professors Matthew…

Transforming Arizona’s highways for a smoother drive

Imagine you’re driving down a smooth stretch of road. Your tires have firm traction. There are no potholes you need to swerve to avoid. Your suspension feels responsive. You’re relaxed and focused on…