3D printing at the nanoscale produces powerful possibilities

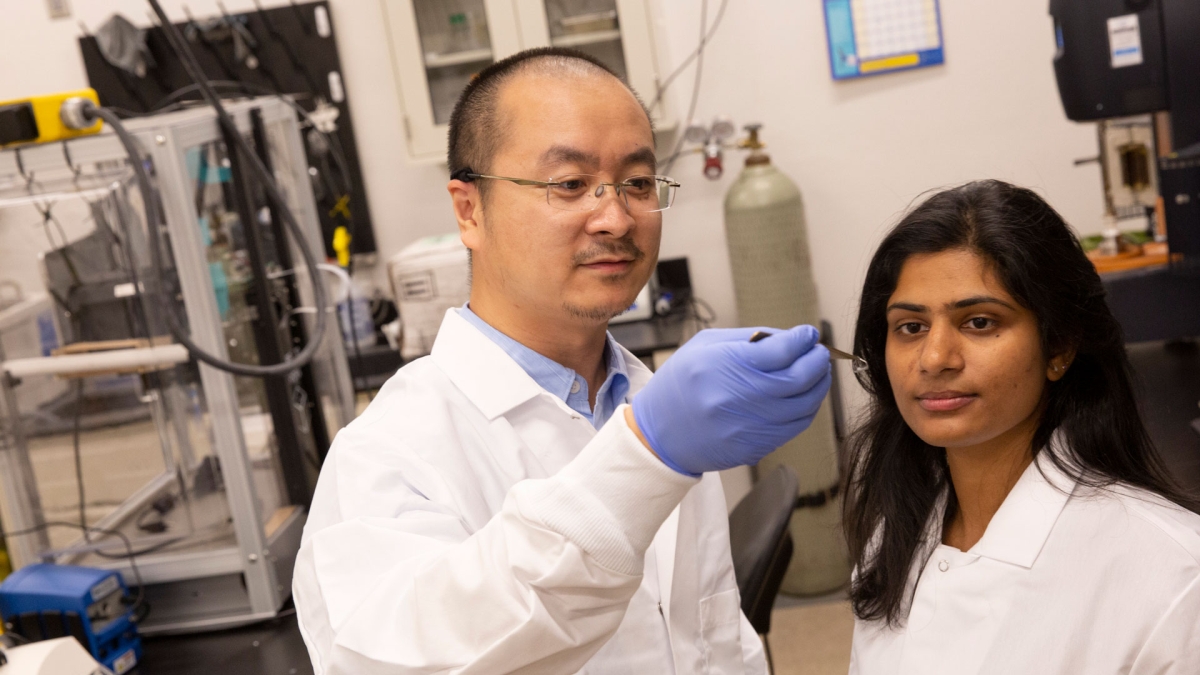

ASU Assistant Professor Kenan Song (left) examines a 3D-printed sample of the Multiphase Direct Ink Writing technology with recent master’s degree graduate and research collaborator Mounika Kakarla. Song earned a 2022 National Science Foundation Faculty Early Career Development Program (CAREER) award for this method, which can enhance 3D printing precision of ordered patterns at very small scales with a wider range of nanomaterials. Photo by Erika Gronek/ASU

Kenan Song is excited about the potential of additive manufacturing, also known as 3D printing. Its ability to allow for inexpensive and rapid prototyping of custom designs without the limits of traditional manufacturing drives his interest in the field.

Song, an assistant professor of engineering in the Ira A. Fulton Schools of Engineering at Arizona State University, is also interested in precise, consistent and efficient production using additive manufacturing. Some of his current research focuses on the exact replication of printed patterns at the nanoscale, with particles more than 1,000 times smaller than the thickness of a sheet of paper.

In nanomanufacturing, particularly when it is used in the semiconductor industry, nanoparticles in the form of powders are used to print ordered structures such as dots, lines, pillars and layers. The properties of the nanoparticles are unleashed based on how they are patterned, so it is critical to be able to print them exactly as designed.

“Precise nanomanufacturing that enables patterning on surfaces or interfaces is critical to transferring high-performance nanoparticle properties when scaled up in devices, such as the chips in iPhones,” Song says, noting that the nature of the irregular nanoparticle powders makes this difficult to achieve consistently.

Current additive manufacturing methods use external forces such as electricity, magnets and sound waves to accurately place nanoparticles at certain locations. However, these methods don’t work for all kinds of nanoparticles and have other limitations.

So Song is developing a new 3D printing mechanism called Multiphase Direct Ink Writing to enhance manufacturing precision at very small scales with a wider range of materials.

This work — a project titled “Additively Manufactured Nanomaterial Layers with Submicron Structures” — is supported by a 2022 National Science Foundation Faculty Early Career Development Program (CAREER) award. This award, which supports Song with $600,000 in funding over five years, is given to young faculty members who demonstrate the potential to be education and research leaders and advance the mission of their organizations.

“With unprecedented speeds and resolutions, our additive manufacturing method will provide a fundamental understanding of 3D printing principles involving both machine design and material science studies,” says Song, who is making significant contributions to manufacturing at the ASU Polytechnic campus as a faculty member in The Polytechnic School in addition to his role as a graduate faculty member in aerospace and mechanical engineering, and materials science and engineering, in the School for Engineering of Matter, Transport and Energy, two of the seven schools in the Fulton Schools.

To create this method, Song is leading a multidisciplinary research effort that includes polymer science, nanoparticle synthesis and interfacial engineering to explore interactions of materials at the atomic or molecular level.

The Multiphase Direct Ink Writing method has broad potential use in the rapid prototyping of sensors, actuators and soft robotics, as well as applications in supercapacitors, batteries and regenerative medicine.

Song and his research team will use the method to develop a class of nanoparticles called MXenes with new structures and physical and chemical properties to demonstrate new 3D-printed energy devices.

Another important aspect of CAREER award projects is their educational component. Song is highly involved in including students from underrepresented groups in his research, teaching an entrepreneurial mindset and providing opportunities for research exchange with universities in Israel, France and Qatar.

He believes his efforts in these areas caught the NSF’s attention as he works to increase diversity in the important, growing additive manufacturing industry.

More Science and technology

ASU and Deca Technologies selected to lead $100M SHIELD USA project to strengthen U.S. semiconductor packaging capabilities

The National Institute of Standards and Technology — part of the U.S. Department of Commerce — announced today that it plans to…

From food crops to cancer clinics: Lessons in extermination resistance

Just as crop-devouring insects evolve to resist pesticides, cancer cells can increase their lethality by developing resistance to…

ASU professor wins NIH Director’s New Innovator Award for research linking gene function to brain structure

Life experiences alter us in many ways, including how we act and our mental and physical health. What we go through can even…