Editor’s note: This story is featured in the 2021 year in review.

An advanced technology lab has moved its headquarters to the Innovation Zone at Arizona State University’s Polytechnic campus in Mesa.

MECHnano, a manufacturer of advanced chemistry and materials that improve the performance of 3D-printing ingredients, is the first company to move to the district, one of seven ASU Innovation Zones across the Valley.

MECHnano CEO Steve Lowder said the move was locked in by the opportunity to work closely with students and the university.

“When I saw the plans for the innovation district I became extremely excited,” Lowder said. “It's something that I've thought about for a long time with respect to industry and education working together. … One of my startups was based out of the U.K. We were right there with universities in the U.K. … I've seen the benefits that come out of it and that's what we were looking for.”

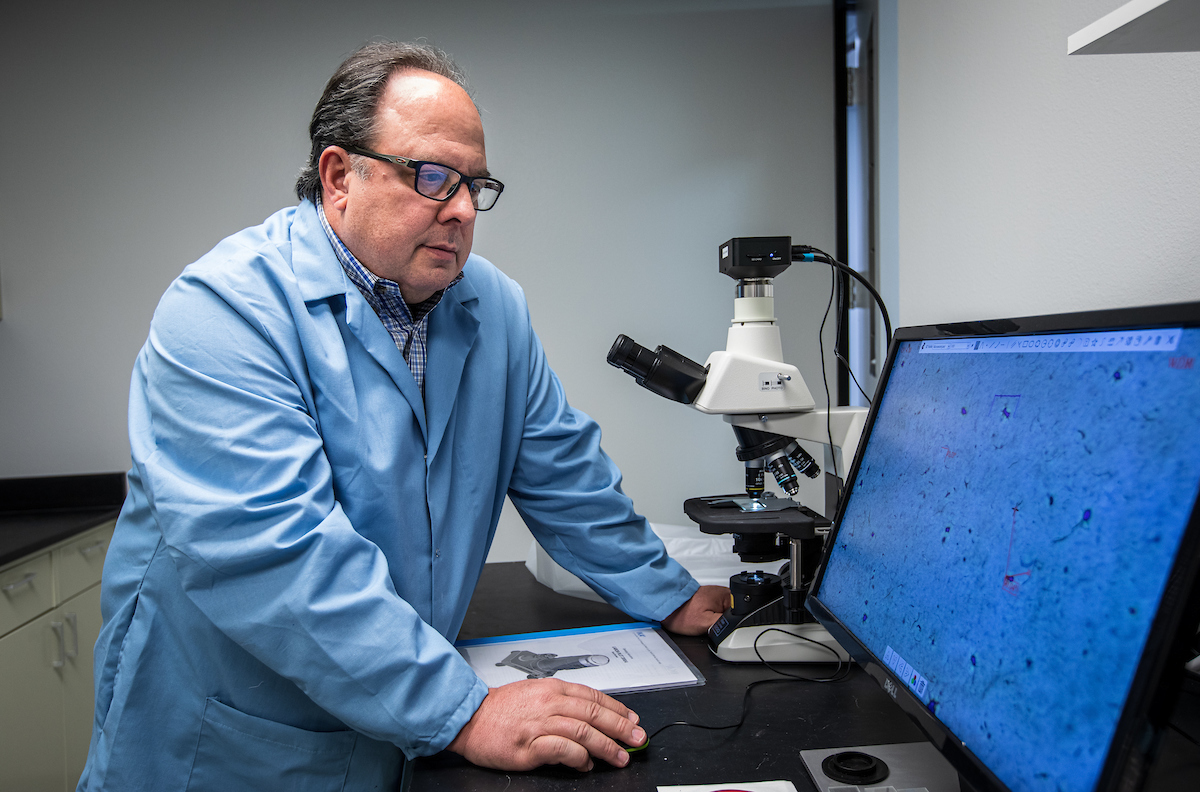

MECHnano’s co-founder and chairman Steve Lowder takes measurements on carbon nanotube clusters in the company's fabrication facility in an old life sciences lab on the Polytechnic campus in Mesa, on March 31, 2021. The nanotubes naturally are attracted to each other and form blobs or clumps. MECHnano is developing technology to minimize the clumping, which makes them more useful for adding lightweight strength, magnetic or conductive properties. The small company holds patents in additive manufacturing with carbon nanotubes, allowing substantial benefits for precision, strength, flexibility and other material properties. The company is part of the new Innovation Zone at the Polytechnic campus. Photo by Charlie Leight/ASU News

Lowder has also worked with universities in Colorado, Louisiana and Georgia.

“I've always had good experiences,” he said. “I saw a mutual benefit to those when we began this startup. … It became obvious that a relationship with the local university and specifically ASU would be very beneficial to us. That is augmented by the fact that ASU reached out to us a little bit as well after our first contact.”

The small company holds patents in additive manufacturing with carbon nanotubes. MECHnano’s technology enhances the material at the nano level allowing substantial benefits for precision, strength, flexibility and other material properties. The nanotubes, which are about 1/10,000 the diameter of a human hair, are as strong as steel, as hard as diamond and as conductive as copper.

An array of test specimens fabricated using MECHnano’s radiation curable resins modified with carbon nanotubes. Parts were fabricated via vat photopolymerization technique, and taken out of the build chamber. Photo by Olga Ivanov/MECHnano

Students will benefit from working at the very cutting edge of technology. MECHnano is the only 3D-printing materials company in the world to have unlocked the potential of carbon nanotubes. ASU students will have a unique and real-world learning experience. The company will benefit from the student perspective, Lowder said.

“Some of the benefits that we get are we're able to move the company forward with high-caliber young minds and very innovative minds because ASU is just probably the most innovative school that I've seen in all the workings that I've had with universities,” he said.

“The student's going to learn a lot — just magnitudes over what you would learn by education itself.”

Company researchers will benefit by rubbing shoulders with scientists working in the same fields only steps away.

Olga Ivanova, the director of technology, goes over calculations at MECHnano’s headquarters.

“Sometimes (research and development) groups can be so corporate-focused that you start to lose a step,” Lowder said. “And then education sometimes is so educationally focused that they don't think about commercialization as much as they need to. For us being located here at ASU and having some of the best scientists in the world on our side really is a good balance between those things.”

The company’s move to the Polytechnic campus is a big win for ASU and Mesa, said Duane Roen, vice provost and dean of the College of Integrative Sciences and Arts.

“We've been working at getting businesses and industry interested in the Polytechnic campus and to start working on the innovation district,” Roen said. “And so we're thrilled about this. MECHnano is just the exact kind of company that we would love to see there. It's a company that works on nanotechnology and we are so interested in companies that do work that relates to the work that occurs at ASU, particularly the Polytechnic campus, so that students have opportunities for internships and for research and faculty can work on research projects as well.”

Aric Bopp, executive director of economic development at ASU Knowledge Enterprise, was instrumental in landing the company. Bopp leads the university’s economic development efforts, with a specific focus on development of the NOVUS Innovation Corridor and other ASU Innovation Zones.

“I'm personally amazed that more companies don't locate closer to campuses,” Bopp said. “It doesn't have to be just ASU, but so many companies struggle with talent acquisition and talent development, and then you ask them, ‘Oh, what relationship do you have with such and such college, a university?’ And they really haven't taken the time. It is a dedicated strategy that they have to implement, but it amazes me that not more companies set up some sort of development center or some sort of lab or some sort of facility closer to campuses.”

Top image: An array of test specimens fabricated using MECHnano’s radiation curable resins modified with carbon nanotubes. Parts were fabricated via vat photopolymerization technique. Photo by Olga Ivanov/MECHnano

More Science and technology

Large-scale study reveals true impact of ASU VR lab on science education

Students at Arizona State University love the Dreamscape Learn virtual reality biology experiences, and the intense engagement it creates is leading to higher grades and more persistence for biology…

ASU-led space telescope is ready to fly

The Star Planet Activity Research CubeSat, or SPARCS, a small space telescope that will monitor the flares and sunspot activity of low-mass stars, has now passed its pre-shipment review by NASA.…

ASU at the heart of the state's revitalized microelectronics industry

A stronger local economy, more reliable technology, and a future where our computers and devices do the impossible: that’s the transformation ASU is driving through its microelectronics research…