Scientists at Arizona State University are celebrating their recent success on the path to understanding what makes the fiber that spiders spin — weight for weight — at least five times as strong as steel.

One of the fundamental mysteries of spider silk that has limited scientists’ ability to produce artificial silks of the quality of natural silks has just been explained by researchers in ASU’s School of Molecular Sciences in collaboration with a team from San Diego State University and Northwestern University.

Their results, published online today in the Proceedings of the National Academy of Sciences (PNAS), are in a paper titled “Hierarchical spidroin micellar nanoparticles as the fundamental precursors of spider silks.”

"Spider silk has a unique combination of mechanical strength and elasticity that make it one of the toughest materials we know," said Jeff Yarger, professor in the School of Molecular Sciences in the College of Liberal Arts and Sciences.

Spider silk is an exceptional biological polymer, related to collagen (the stuff of skin and bones) but much more complex in its structure. The ASU team of chemists is studying its molecular structure in an effort to produce materials for uses ranging from civil and mechanical engineering to artificial, yet biocompatible, tendons.

“Everybody’s familiar with silk, because they’re familiar with silkworm silk. The silk trade has been around for a long time. But spider silk has a much larger variety in its properties,” Yarger explained.

Unfortunately, spiders don’t produce silk in large quantities. “You can put lots of silkworms in a small area and genetically modify them to go from the larval state to a moth in 20 to 30 days. Spiders take longer. But let’s get to the crux of it — spiders don’t like each other. They eat each other,” Yarger said. This, of course, eliminates the possibility of farming them en masse.

Scientists have come up with ingenious ways to get around this problem. They have genetically engineered silkworms, E. coli and even goats to produce spider silk. Unfortunately, while these organisms produce the same proteins that spiders make, they don’t have the same mechanical properties as the natural product. They aren’t as strong, for instance, or as flexible.

This is where the current research comes in — Yarger was joined by Dian Xu, Samrat Amin and Brian Cherry, all from ASU; Gregory Holland, associate professor of chemistry from San Diego State University; and Nathan Gianneschi, professor of chemistry from Northwestern University.

“In a matter of milliseconds, a spider can take a concentrated protein solution stored in its abdomen and pull this material rapidly through ducting and spinnerets to produce silk fibers,” Yarger said.

“Understanding at the molecular level how spiders perform this complex process, and reproducing it in the lab, is the primary research objective within our group.”

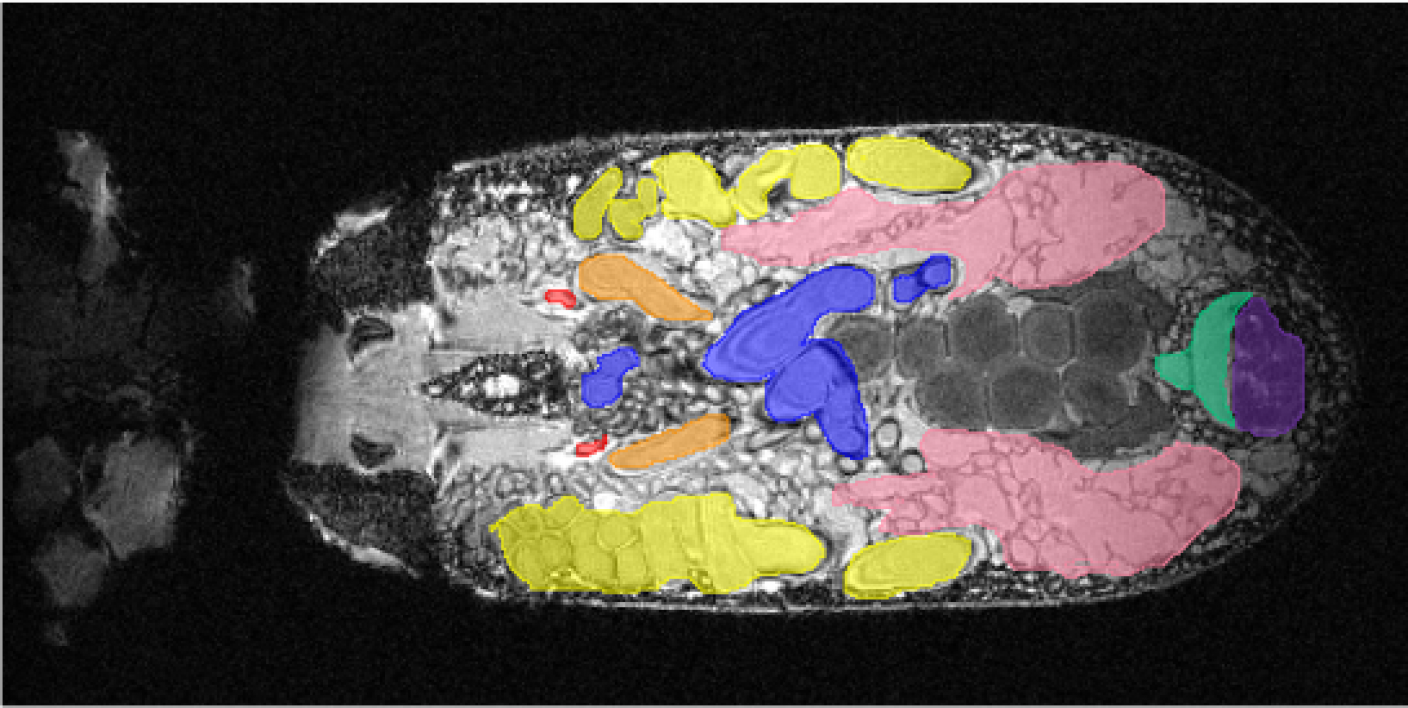

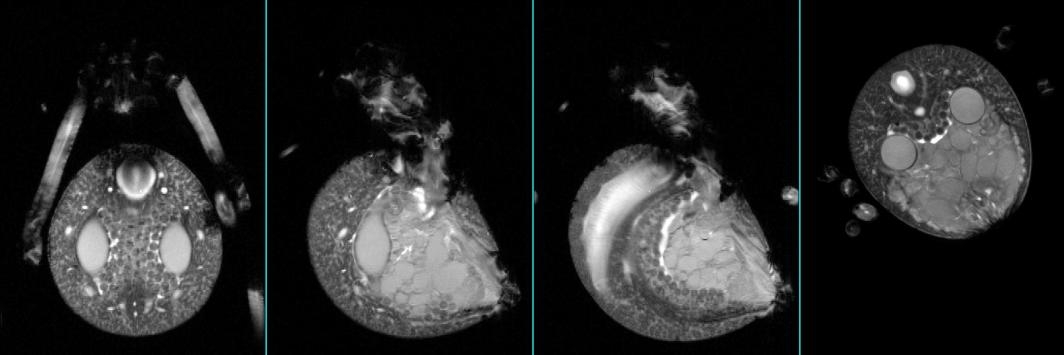

The team employed a suite of magnetic resonance tools — NMRNMR stands for nuclear magnetic resonance. The term is used interchangeably with MRI, or magnetic resonance imaging. (or MRI) at ASU and San Diego State as well as cryo transmission electron microscopy at Northwestern University. They studied the precursor solution of the dragline silk of local black widow (or Latrodectus hesperus) spiders.

“We are now a step closer to a molecular understanding of this process,” Yarger said. “We have discovered a hierarchical micellar nanoparticle structure based on the molecular organization of the proteins stored in the abdomen of spiders. This has led us to the first molecular-level model of spider silk protein fiber formation and hopefully one step closer to lab production of spider silk protein fiber.”

This research was primarily funded by grants from the Department of Defense, Air Force Office of Scientific Research, the U.S. National Science Foundation (Division of Materials Research, Biomaterials) and ASU (Magnetic Resonance Research Center).

Top photo: An Argiope spider — whose silk is being studied by the Yarger group — is pictured in the Magnetic Resonance Research Center, in the basement of ASU’s Interdisciplinary Science and Technology 1 building.

More Science and technology

Science meets play: ASU researcher makes developmental science hands-on for families

On a Friday morning at the Edna Vihel Arts Center in Tempe, toddlers dip paint brushes into bright colors, decorating paper fish. Nearby, children chase bubbles and move to music, while…

ASU water polo player defends the goal — and our data

Marie Rudasics is the last line of defense.Six players advance across the pool with a single objective in mind: making sure that yellow hydrogrip ball finds its way into the net. Rudasics, goalkeeper…

Diagnosing data corruption

You are in your doctor’s office for your annual physical and you notice the change. This year, your doctor no longer has your health history in five-inch stack of paperwork fastened together with…