Editor’s note: This is part of a series of profiles for spring 2017 commencement. See more graduates here.

For Cody Van Cleve’s senior design project, the engineering undergrad and five teammates secured a robotic manipulator arm and a check for $25,000 from Delta Technologies Inc., a Phoenix-based custom industrial manufacturing automation company. The six-person team worked 30 to 40 hours per week since October to build an automation demonstration cell. The control cabinet — the brains of the system — took 400 hours alone to build. They did all the welding and painting from scratch.

“We weren’t expecting to go that deep,” Van Cleve said. “It was a lot of work. ... It’s not something we had instructions or plans for. We just made it.”

It’s an arm inside a very high-tech enclosure (a laser wall shuts the whole thing down if someone sticks their hand inside), which gathers metal pieces and puts them in a frame to spell different words. As Van Cleve pointed out, it doesn’t really do anything, but it successfully demonstrates the full range of movement and precision necessary for manufacturing. Delta would charge $150,000 to build something similar.

“I’m hoping this shows industry partners what students can do when they have a real budget,” said the Tucson native, who is graduating with a B.S. in engineering/robotics and manufacturing from the Polytechnic School, which is part of the Ira A. Fulton Schools of Engineering. “The amount we were able to learn is incredible ... I feel a lot more confident after the project.”

He answered some questions about his time at ASU:

Question: What was your “aha” moment, when you realized you wanted to study the field you majored in?

Answer: This campus was kind of my aha moment. I’d looked at all the other state universities. It’s financially limiting to look anywhere else. I hadn’t looked at the Polytechnic campus until a month or two before graduation. I came out here, and I saw what everyone was doing and I was transfixed by it. This place was what made me realize I wanted to be here — the environment itself. It’s incredible.

Q: What’s something you learned while at ASU — in the classroom or otherwise — that surprised you, that changed your perspective?

A: The emphasis they have on business really surprised me in a good way. I was kind of torn between business school and engineering school, actually. When I came here they have so many efforts to promote entrepreneurship and student business ventures making you conscious that what you do is always going to have an impact. How do you design a product that people actually want to buy vs. just how do you design a product. That was interesting to me, and that’s what I wanted, so this ended up being the perfect environment for me. I got lucky.

Q: What’s the best piece of advice you’d give to those still in school?

A: The biggest piece of advice that helped me is that there is a bigger impact to what we’re doing, realizing you’re never working in a vacuum and what you’re doing has an impact on people around you, whether you know it or not. Trying to figure out what that is can either help move you forward or hold you back.

Q: What was your favorite spot on campus, whether for studying, meeting friends or just thinking about life?

A: Probably this lab. This is where all the fun people hang out and we get to work on incredible things.

Q: What are your plans after graduation?

A: I actually just turned down a couple of job offers to do another year in school for a master’s. I enrolled specifically in a bunch of sustainability courses, because I want to figure out how to apply manufacturing and controls and everything else to alternative energies. It makes me happy that I’m working on something progressive. It’s hard to break out of that mentality of getting a job in a field that’s existed for so long vs. trying to push forward and do something different. I want to be part of that, figuring out how to move us forward rather than stay where we are.

Q: If someone gave you $40 million to solve one problem on our planet, what would you tackle?

A: I think the biggest problem we have is that we’re not prepared to deal with the future we’re making. I would make it easier for people to have access to alternative energies. Right now electric cars and alternative technologies are higher-end expensive items. A lot of people can’t choose between living sustainably and living the way it is because it’s cheaper the way it is. I would use that money to make things more accessible to people.

Top photo: Cody Van Cleve holds the controller to the six-axis robotic manipulator arm, part of the capstone project he and five others created with more than $20,000 from Delta Technologies Inc. The automation demonstration cell is designed in this instance to place red blocks into spaces to create a sign. Van Cleve will be graduating with a bachelor's in robotics and manufacturing from the Ira A. Fulton Schools of Engineering. Photo by Charlie Leight/ASU Now

More Science and technology

ASU and Deca Technologies selected to lead $100M SHIELD USA project to strengthen U.S. semiconductor packaging capabilities

The National Institute of Standards and Technology — part of the U.S. Department of Commerce — announced today that it plans to award as much as $100 million to Arizona State University and Deca…

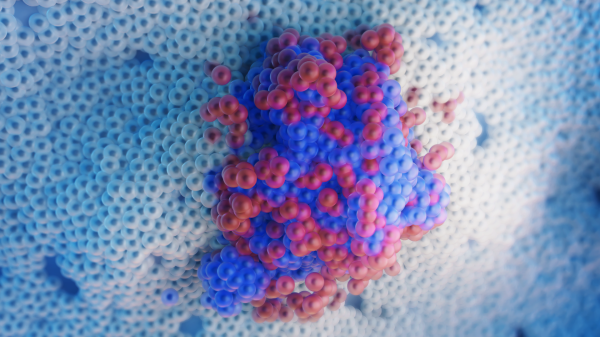

From food crops to cancer clinics: Lessons in extermination resistance

Just as crop-devouring insects evolve to resist pesticides, cancer cells can increase their lethality by developing resistance to treatment. In fact, most deaths from cancer are caused by the…

ASU professor wins NIH Director’s New Innovator Award for research linking gene function to brain structure

Life experiences alter us in many ways, including how we act and our mental and physical health. What we go through can even change how our genes work, how the instructions coded into our DNA are…