The everyday act of drinking a glass of water from your faucet may be a greater hazard to your health than you imagined.

The Environmental Protection Agency says that perfluoroalkyl and polyfluoroalkyl substances (PFAS) are dangerous, even in amounts so small as to be undetectable in drinking water. Currently, there are no federal restrictions for how much of these “forever chemicals,” as they are also called, can trickle through your tap.

The EPA has proposed a national drinking standard for PFAS, but experts say removing them could cost billions of dollars. For communities with the pollutants, it’s a costly problem to solve.

But researchers at Arizona State University have developed a new method that helps microorganisms destroy PFAS. The technology may prove to be more cost-effective and nonpolluting than alternative technologies.

Data compiled by the Environmental Working Group, a nonprofit advocacy organization, reveals that PFAS lurk in the drinking water of more than 200 million Americans, or more than 60% of the country’s population. The compounds may take hundreds or even thousands of years to break down in the environment.

They also linger in the human body. A large number of studies suggest that high levels of certain PFAS in the body may lead to health problems ranging from high cholesterol to pregnancy complications to increased risk of some cancers. Scientists are still learning about the true scope of PFAS-related health effects.

The first use of PFAS was as the nonstick agent in Teflon in 1938, and they’ve since been added to fast-food packaging and countless household items — from stain-resistant carpeting and cleaning products to shampoo and dental floss.

Products coated in PFAS resist sticking and staining because of their unique chemical composition, made by fusing carbon and fluorine atoms. Other molecules can’t break that bond, so they slide right off. But this also means the chemicals are nearly indestructible.

“The carbon fluorine bond is the strongest known carbon bond in chemistry,” says Bruce Rittmann, Regents Professor in ASU’s School of Sustainable Engineering and the Built Environment.

Because of this, PFAS have found their way into rainwater, soil, sediment and drinking water — and inside the living tissues of humans and animals around the world.

Bruce Rittmann

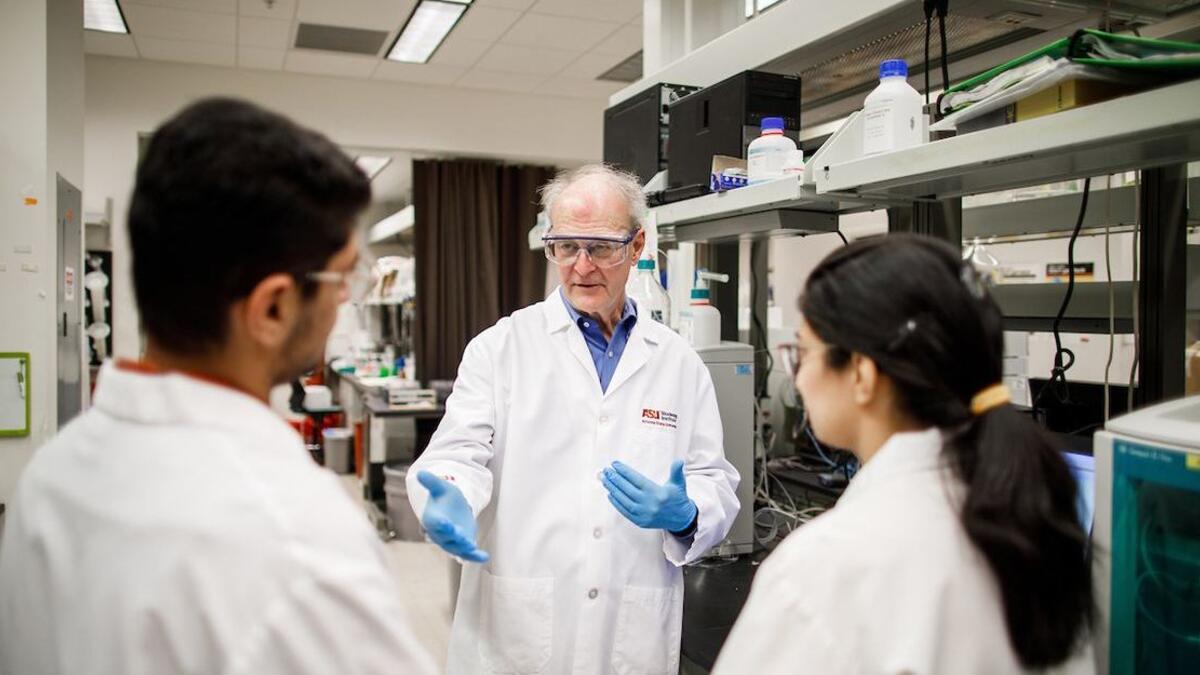

Rittmann is the director of the Biodesign Swette Center for Environmental Biotechnology. There, he and his research team have discovered an unorthodox way to break PFAS down — by introducing them to a team of microorganisms that act like PFAS assassins.

These bacteria are too small to be seen by the human eye, but they can play a huge role in removing harmful contaminants from water, including PFAS.

“In our research center, we study microorganisms — who they are, what they can do, what controls what they actually do, and how they interact with each other,” he says. “A microbial community is an assemblage of microorganisms that are doing different things, working together as a team. You can think of them as a sports team with different players in different positions. Or you can think of them as an orchestra with different musicians performing a symphony.”

The winner of the 2018 Stockholm Water Prize, often described as the Nobel Prize for water, Rittmann is a pioneer in the use of microorganisms for wastewater treatment.

Among his long list of accomplishments is the invention of the membrane biofilm reactor (MBfR). The MBfR uses naturally occurring microorganisms to remove contaminants from water. Rittmann holds five patents on the technology, which is being commercialized by Precient Technologies, based in Tempe, Arizona; JSREET, based in China; and APTwater, based in California.

Rittmann explains how the MBfR works.

“In the MBfR, we are using hollow-fiber gas-transfer membranes. A hollow fiber is like a very tiny straw. And we use the straw to deliver hydrogen gas to microorganisms. As hydrogen is delivered on the inside of the straw, it diffuses through the wall. On the outside, a biofilm of microorganisms oxidizes the hydrogen,” he says.

As the bacteria oxidize the hydrogen, they also pull out harmful contaminants such as perchlorate and trichloroethene from the water.

To help the bacteria break down PFAS, Rittmann modified the MBfR technology to create a new one: a membrane catalyst film reactor, or MCfR. Instead of bacteria, a film of palladium-based nanoparticle catalysts is deposited on the outside of the membrane or straw.

“Palladium, one of the platinum group metals, is famous for being a catalyst in its solid elemental form,” he says. “That means it speeds up a lot of reactions. And one of the reactions it will speed up is the reductive defluorination of PFAS, which means replacing fluorine atoms with hydrogen atoms.”

Together, the two technologies perform a one-two punch to knock off the fluorine atoms in the MCfR, which transforms a forever chemical into a biodegradable one.

“We use the MCfR to knock off a few to all of the fluorines, and then we hand that water with those compounds over to the microorganisms in the MBfR, and they finish the job,” Rittmann says. “We’ve shown that it works with all the PFAS compounds we’ve tried so far.”

After a solid track record of success in the laboratory using reactors the size of a water bottle, it’s time to gear up for future field testing at contaminated sites. The researchers’ next step is to scale up the technology to a larger, real-world configuration and conduct experiments in the lab and then in the field.

This research is supported in part by the Nanotechnology Enabled Water Treatment center, or NEWT, led by and based at Rice University in Houston. Funded by a renewable NSF grant, NEWT brings together experts from ASU, Rice, the University of Texas at El Paso and Yale University. Its goal is to facilitate access to clean water almost anywhere in the world by developing efficient, easy-to-deploy modular water treatment systems that are based on nanomaterials.

"You can think of (a microbial community) as a sports team with different players in different positions. Or you can think of them as an orchestra with different musicians performing a symphony."

— Bruce Rittmann, director of the Biodesign Swette Center for Environmental Biotechnology

Nationwide, researchers are exploring methods to dispose of PFAS, which typically rely on expensive and harsh treatments, some of which require high pressures and temperatures above 1,000 degrees Celsius. There’s evidence that incinerating products containing PFAS can lead to the spread of these compounds in the environment, creating a need for methods, such as Rittmann’s, to get rid of PFAS in a way that doesn’t continue to pollute.

Beyond removing harmful contaminants from water, the MBfR technology also demonstrates potential to cut wastewater treatment costs, reduce energy consumption and even recover precious metals for recycling.

For microorganisms, these activities are just part of everyday life. Rittmann’s job is to get them to do it reliably.

“We study the microorganisms deeply so that we can think like them. We learn how we can work for the microorganisms so that they can work for us. It is an ideal win-win situation, a true partnership between the microbial workers and the human managers to do a job, such as cleaning up PFAS pollution,” he says.

Rittmann’s work is “leading to new ways to clean up pollution, treat water and wastewater, capture renewable energy, and improve human health,” wrote Rao Surampalli, an emeritus engineering director for the U.S. Environmental Protection Agency, in his nomination of Rittmann as a Water Environment Federation FellowThe WEF Fellowship is one of many accolades Rittmann has received throughout his career. He has been named a fellow in the International Water Association, National Academy of Inventors and the American Association for the Advancement of Science. He is a member of the U.S. National Academy of Engineering and a Distinguished Member of the American Society of Civil Engineers. A prolific researcher, he has written more than 800 peer-reviewed scientific papers and is co-author of the textbook “Environmental Biotechnology: Principles and Applications,” used in university classrooms worldwide..

Rittmann has been a pioneer in how we think about wastewater and water treatment since 1984, when he proposed the idea that microorganisms should be incorporated in the treatment of drinking water.

“In the past, the concept of drinking water in the United States was that all bacteria are bad and we should get rid of them,” he says. “So traditional technologies in drinking water treatment have been to kill bacteria. The field has now changed. What we call biofiltration is a relatively common feature of drinking-water treatment now, although it took a long time for this concept to gain a foothold.”

Top photo: Bruce Rittmann, director of the Biodesign Swette Center for Environmental Biotechnology, works with two fellow researchers in the laboratory. Photos courtesy Arizona State University

More Science and technology

Extreme HGTV: Students to learn how to design habitats for living, working in space

Architecture students at Arizona State University already learn how to design spaces for many kinds of environments, and now they can tackle one of the biggest habitat challenges — space architecture…

Human brains teach AI new skills

Artificial intelligence, or AI, is rapidly advancing, but it hasn’t yet outpaced human intelligence. Our brains’ capacity for adaptability and imagination has allowed us to overcome challenges and…

Doctoral students cruise into roles as computer engineering innovators

Raha Moraffah is grateful for her experiences as a doctoral student in the School of Computing and Augmented Intelligence, part of the Ira A. Fulton Schools of Engineering at Arizona State University…