Editor’s note: This is the latest installation in a yearlong series about ASU's Formula SAEFormula SAE is a student design competition organized by the International Society of Automotive Engineers (now known as SAE International). team. Find links to previous stories at the end of this article.

If the story of the Arizona State University student engineers building a race car for a June competition were a movie, this would be the part where the broken and bloodied hero lifts his head and knows he’s got a fighting chance.

In the past few weeks they made mistakes, took hits and lost money and morale.

Now they’re back in the race.

It’s the first Saturday of spring break. Yet in a machine shop in the back of the Psychology North building on the Tempe campus, the only sign of a holiday is electronic dance music pulsing in between the whine of metal grinders.

These are the students of the Formula Society of Automotive Engineers, working on a design competition to build a Formula-style race car. The concept behind the competition is that a fictional manufacturing company has contracted a design team to develop a small Formula-style race car. The prototype is to be evaluated at the competition in Nebraska for its potential as a production item. Each team designs, builds and tests a prototype based on a series of rules.

‘In a pretty good pinch’

The ASU team has been struggling for the past three weeks. They made a mistake cutting the suspension tabs that hold the A arms, which support the wheels.

“It pulled us back in so many ways,” team manager Troy Buhr said.

The Formula SAE team's chief engineer, Wes Kudela, TIG welds supports on the car's A arms, which support the wheels, on March 5, the first Saturday of spring break, in Tempe.

Photo by Charlie Leight/ASU Now

“We didn’t know we weren’t cutting to the exact tolerances, so we lost $600,” team chief engineer Wes Kudela said. “We were in a pretty good pinch.”

The suspension tabs are curved to fit the chassis tubes, and they need to fit to a 32nd of an inch tolerance. K-zell Metals, a Phoenix fabricator, laser-cut the new suspension tabs. The team began to mount them Saturday.

This week they plan to take advantage of spring break to mount the upper and lower A arms on the chassis, bolt the hubs on and mount the wheels.

“There’ll be activity every day,” said Kudela, a senior in mechanical engineering. “I feel like this spring break is going to make me a lot less stressed.”

The new hubs are waiting to be machined at the ASU Machine Shop. Until then, the team is mounting the old hubs.

“Then we’ll have a rolling chassis,” said Buhr, a junior in mechanical engineering. “It’ll start looking like a car. It’ll shoot spirits up. It’s a big thing.”

Doing a pace-car lap at the Indy races at Phoenix International Raceway — an April thrill the team was hoping for — likely isn't going to happen. The team would have had to buy a policy with a million dollars in liability. Now Buhr is working on getting insurance for a static display of the car at PIR. “I’ve gone into plea mode,” he said. “I don’t know anything about insurance.”

Meeting that April 2 date at the raceway is the new goal. “That’s what we’re shooting for,” Kudela said.

A glimpse of the real world

A PitchFunder campaign to raise $10,000 for transportation will kick off March 29. The team needs a U-Haul to take the car to the competition in Lincoln, Nebraska; a charter bus for the 30 team members who will be going; and motel rooms for everyone.

“Time is the big thing,” Buhr said. “We’ve always pulled back because of money. ... We have plenty of members putting their heart and soul into the club … (but) we’re not as far ahead as we should be.”

Hexcel, a materials company that makes carbon-fiber and composite materials for aerospace, defense, wind energy and other markets, donated excess honeycomb material that will be sandwiched between carbon-fiber plates on the nose cone. Team members recently had a tour of the Hexcel facilities in Casa Grande.

“It was pretty amazing,” Buhr said. “There might be a couple of guys who get jobs there.”

About 30 team members also toured the Southwest Airlines maintenance facility at Phoenix Sky Harbor International Airport.

“We got to watch them tear down a plane,” Buhr said. “Going out and seeing the actual industry is eye-opening.”

Women on the team

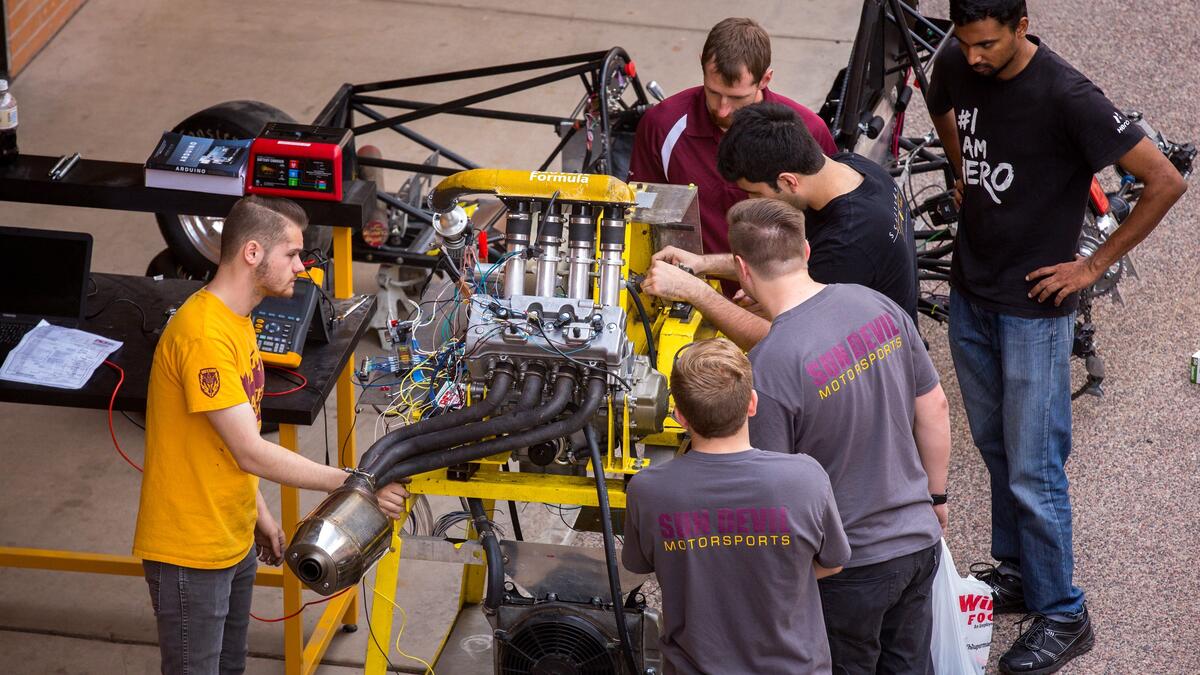

The engine is built and working. It needs to be fine-tuned for optimum performance. The engine team has it up on a table mount, with wires feeding performance data into a laptop and electrical diagnostic equipment.

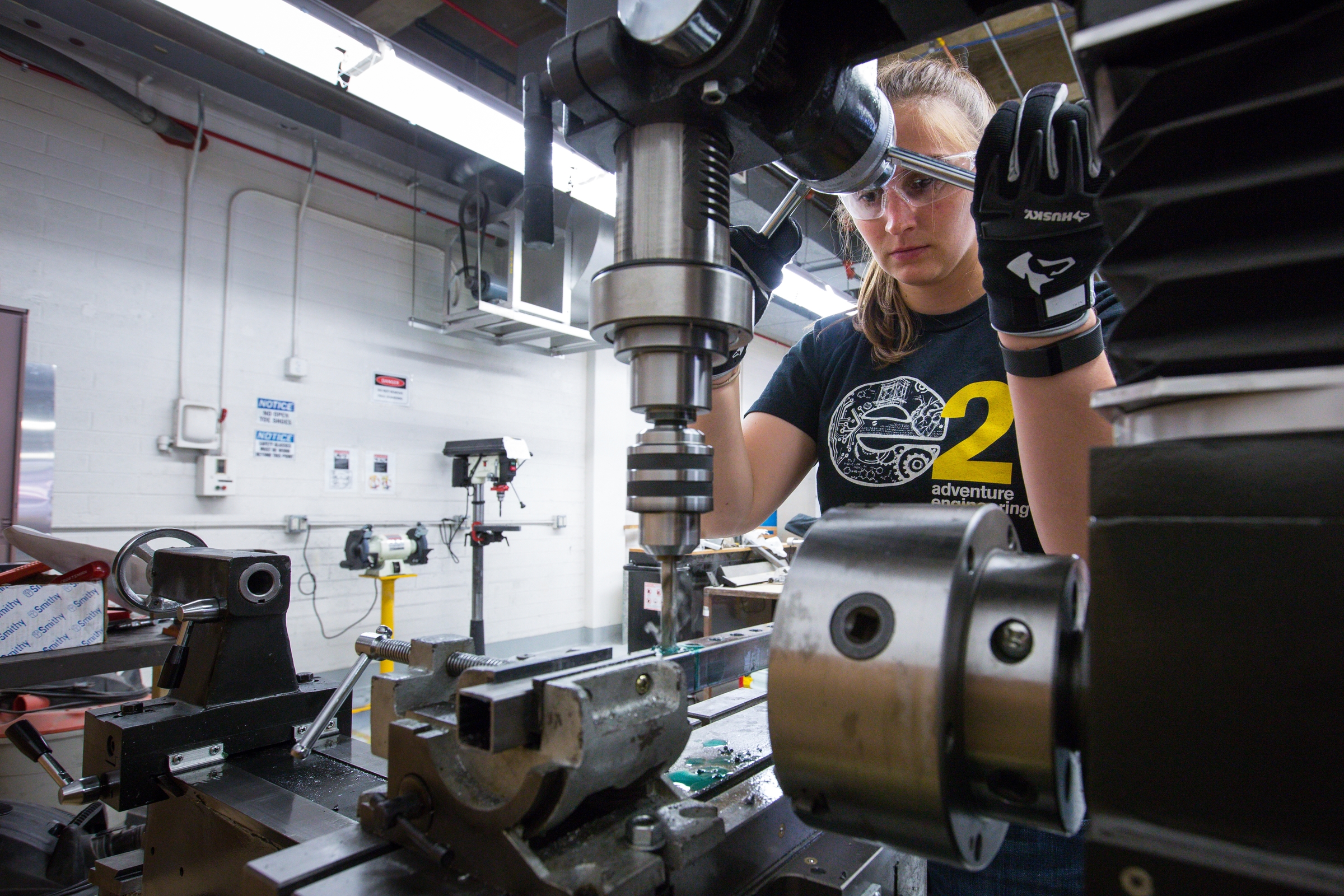

At the back of the shop, team members are drilling holes into a metal tube that will become a pedal mount. They’re good metal workers. They tap the tube with a drill bit, slowly creating a pilot hole so neither the bit nor the metal heats up too quickly and torques the piece out of shape. Among those working is Emily MacMillan, a senior majoring in mechanical engineering.

Needless to say, a workshop where an engineering club is building a race car can be a macho environment. Among the sea of Mopar T-shirts, beards and guys wielding tools, female students stand out like neon lights. The few women in the club say they really enjoy the work.

Emily MacMillan, a senior in mechanical engineering, drills holes in the pedal assembly as work continues on the Formula SAE race car on March 5 on the Tempe campus. Photo by Charlie Leight/ASU Now

MacMillan has been with the club two months.

“I wanted more hands-on experience,” she said. “I have friends in the club, and they really enjoyed it.”

MacMillan has been learning about welding, using a variety of metal-working tools, and measuring. Working in a sea of dudes doesn’t faze her.

“I’m kind of used to it because of my major,” she said. “For me it’s natural. It doesn’t bother me. I wished I’d joined it sooner.”

Across the room, Alejandra Charcas, a sophomore majoring in mechanical engineering, works on a 3-D model of a part. She said she didn’t mind being in the minority either.

“It’s not intimidating,” Charcas said. “Everyone’s really friendly. I actually joined with my friend. We just needed to get involved to put something on a resume. We don’t actually know much about cars. Building a car is super-complicated.”

Charcas always liked chemistry and math in high school.

“I went into civil engineering and just drifted into mechanical engineering,” she said. “Mechanical is really broad; you can take it wherever you want.”

Previous stories in this series:

Oct. 14: Tempe Drift: How an underdog student engineering team is building a race car from the ground up.

Nov. 4: Racing time and money to build a fast car.

Dec. 10: Braking bad: Pressure is on for ASU student engineers building race car

Dec. 17: No brake: ASU team powers through to edge closer to race car

Feb. 1: Coming into the home stretch

More Science and technology

Extreme HGTV: Students to learn how to design habitats for living, working in space

Architecture students at Arizona State University already learn how to design spaces for many kinds of environments, and now they can tackle one of the biggest habitat challenges — space architecture…

Human brains teach AI new skills

Artificial intelligence, or AI, is rapidly advancing, but it hasn’t yet outpaced human intelligence. Our brains’ capacity for adaptability and imagination has allowed us to overcome challenges and…

Doctoral students cruise into roles as computer engineering innovators

Raha Moraffah is grateful for her experiences as a doctoral student in the School of Computing and Augmented Intelligence, part of the Ira A. Fulton Schools of Engineering at Arizona State University…